Supply chains, particularly global and complex supply chains, have lots of moving parts. From production, storing, to transporting goods, there are several stages goods and products pass before reaching a customer.

Unfortunately, a snag in one part of the supply chain can bring everything to a grinding halt. In other words, your supply chain may be one lousy supplier or vendor away from a significant disruption.

Take the case of the great KFC chicken shortage as an example. In February 2018, the company switched to a new third-party logistics provider, resulting in disruptions in the supply of ingredients to its stores. More than half of KFC stores in the UK were forced to close, and KFC incurred up to $1,188,000 daily in costs.

Given how global supply chains operate, it is not possible to avoid risks entirely. Disruptions could occur because of natural disasters—hurricanes, earthquakes, or floods—or political unrest and economic instability. However, supply chains can be made more risk-resilient.

In this article, we’ll walk you through practical ways to build resilience into your supply chain. Let’s start by understanding the concept of supply chain risk management.

Supply Chain Risk Management (SCRM) involves all the processes to identify, assess and mitigate risks in a supply chain. Deloitte reports that companies who proactively manage their supply chain risk spend 50% less to manage disruptions.

Effective SCRM involves three key stages: identification, assessment, and mitigation. Let’s look at each of these in turn.

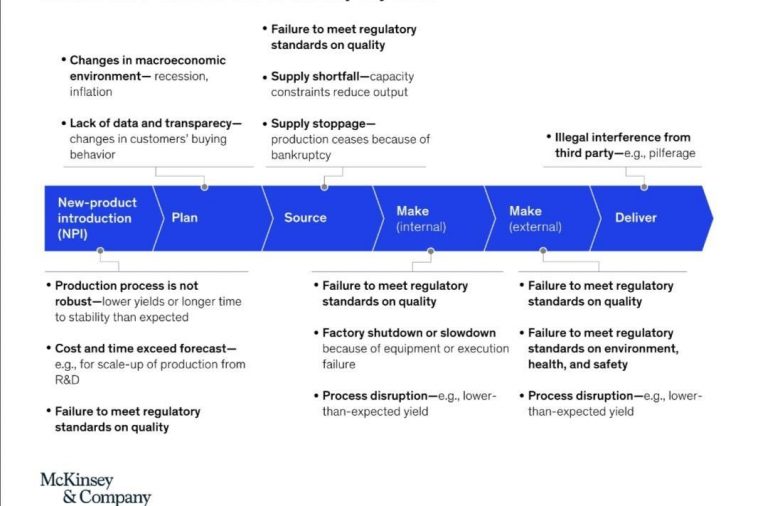

First, an organization must be able to identify its risks and potential vulnerabilities. According to McKinsey and Co., supply chain vulnerabilities show up in five main areas: planning and supplier networks, transportation and logistics systems, financial resiliency, product complexity, and organizational maturity.

Create risk profiles for all elements of your supply chain. Here’s an example of identifying risks by mapping out and assessing all nodes of the value chain.

Source: McKinsey & Co.

With a good understanding of your supply chain, it should be relatively straightforward to identify vulnerabilities. If you need support with the process, you can get support from external consultants that specialize in supply chain analysis.

Once you have identified potential risks, you need to assess their seriousness. There are various frameworks for assessing risks. The risk assessment matrix is one example.

Source: Steve Biz Blog

Through a risk assessment matrix, you categorize risk based on the impact it can have on your business and the likelihood of that event occurring. Some risks will have a significant impact on your supply chain resilience. Other risks will have low associated risks.

Once you have identified the problems and assessed the implications, you need to mitigate the risk. The first step of the process is creating a plan of action. Assess your capacity to action items within your team or the larger business, and then prioritize items based on the payoff.

Some of the risks you identify will be easy to mitigate, and the payoff would be significant if anything occurs. Other risks will be harder to mitigate and have equally serious implications.

For example, let’s assume that your supplier is located in an earthquake-prone zone. After assessing the risk, the next logical step is to have a strategy to reduce that risk. For instance, you can identify alternative suppliers in another region and develop business relations with the company. Taking out a Contingent Business Interruption (CBI) insurance is another preventive action available to you.

These steps are crisis-response actions that ensure that you are ready when the worst happens. Catalog all your preventive and crisis-response measures. Also, assign a responsible party—an individual or a department—to each action.

Your SCRM strategy will be unique to your business. However, there are effective strategies many companies use that you can apply to your business. Let’s walk through a few of the best mitigation strategies.

Sourcing is at the heart of all supply chains. If you are manufacturing or assembling your product in another country, you’ll need to have suppliers and vendors who deliver the goods you require without fail.

Many companies rely on one source for specific parts. While that might reduce the cost of supply and simplify many elements of your supply chain, there is increased risk to working with only one source. The main issue being, if that supplier has any challenges, your entire supply chain will be impacted.

That’s why multiple sources for your supply chain are vital to success.

For every location, have a list of reliable suppliers and vendors who can provide the goods and services you need. Depending on what you are producing, you can split your supplies between different vendors. Keep the rest of the vendors on standby.

I bet you’ve heard the phrase “don’t put all your eggs in one basket.” In the supply chain world, this is perhaps one of the best counsel you can receive. Here are some benefits of a diversified supplier network.

Competition between vendors often drives down prices and fuels innovation. If a supplier knows that you have other options, they are likely to be open to negotiating favorable terms for a contract.

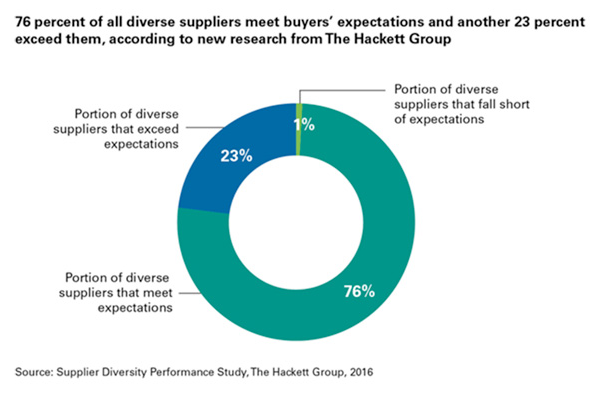

Source: Hackett Group

Research by Hackett’s Group showed that companies who dedicate 20% or more of their spending to diverse suppliers could attribute as much as 15% of their annual sales to supplier diversity programs.

Utilizing more than one supplier allows you to tap into different sources’ strengths while making your supply chain more risk resilient. While managing multiple suppliers will require more resources, especially during the initial stages of the business relationship, there are payoffs.

For example, you can have a supplier who provides pallets for packaging. That supplier may not be as good when it comes to dispatching the products. So, you’ll have to tap into the strengths of another vendor who is excellent at it.

According to Alexis Bateman, research scientist of MIT Sustainable Supply Chains, there are two key traits of transparent supply chains:

Supply chain transparency is crucial to building a risk-resilient supply chain. Whether it’s upstream or downstream from manufacturer/supplier, technology will be a key part of the solution.

The right technology allows you to track every stage of your supply chain. Depending on their sector, you will find companies using GPS, blockchain, DNA tracking, microbiome, near field communication, and the advances in internet availability to monitor their supply chain’s performance.

The great thing about collecting this information is that you can let your clients know where suppliers are in the production or delivery process. Information like this can boost confidence in your company from key business partners.

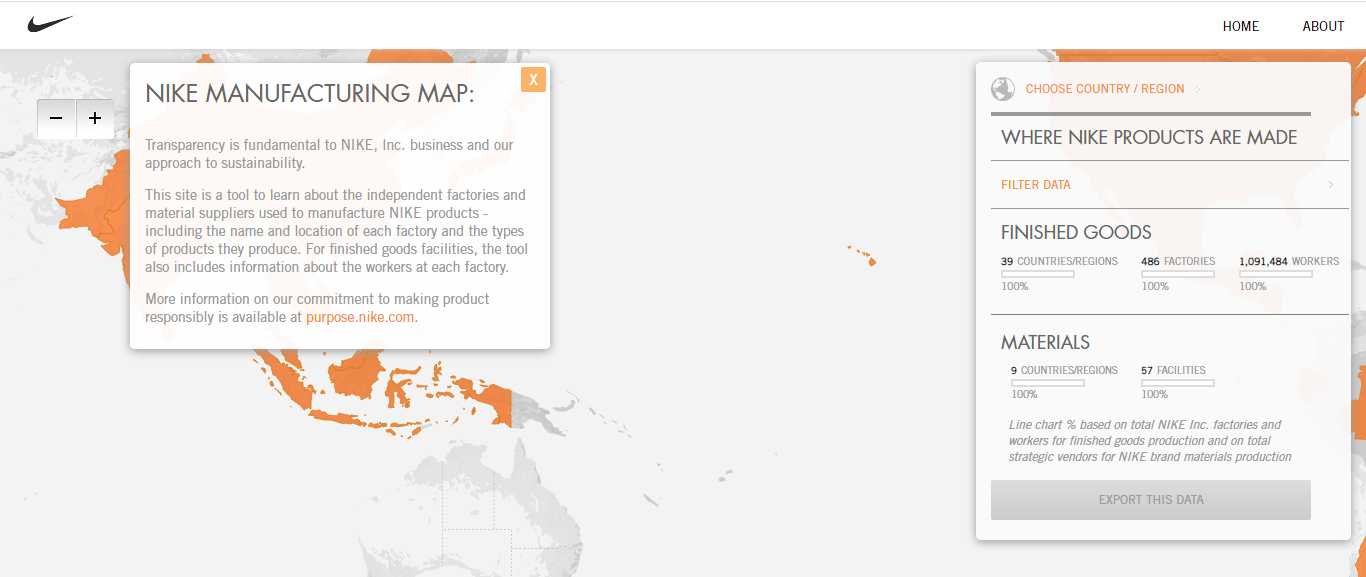

Visibility is particularly helpful for companies in industries where raw materials are sourced from under-developed locations where forced labor and exploitation are common. Nike is a great example of a company that is excelling at public-facing transparency. The company was one of the first to publish its list of suppliers. It also has a manufacturing map that anyone can access.

Source: Nike

The supply map is a nice example of the various ways you can utilize the information you gather. In this case, Nike provides the information they gather to reassure consumers about their ethical business practices.

The foundation of effective SCRM is a comprehensive plan for all potential risks. Your plans must be well-documented and available to all relevant personnel. Your plans should touch on several areas, including:

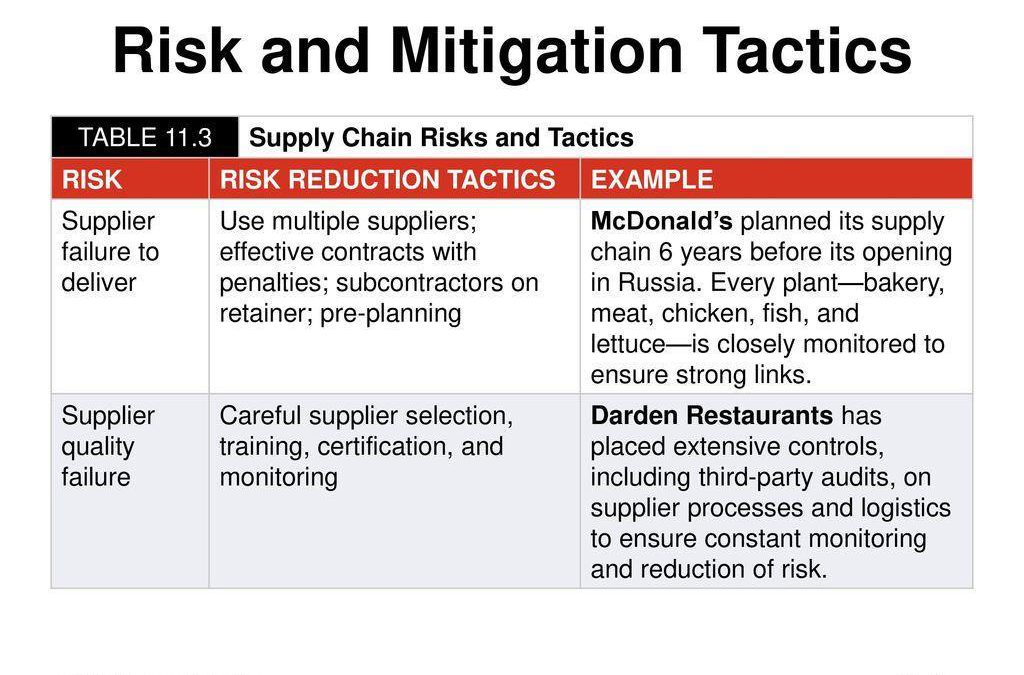

Your plans should cover both internal and external risks. Take note of the risks that are unique to your industry and address them. Here’s an example of risks and the appropriate mitigation strategies:

Source: Pearson Education

Review and update your plans periodically to make them more comprehensive and robust to help your organization navigate tough situations. Periodically review your risks to keep in step with the evolving times.

You can leverage the PPRR model of risk management to map out a clear plan for any emergency. The plan involves Prevention, Preparedness, Response, and Recovery. Read more about how to use the PPRR model here.

Your supply chain is at the mercy of several factors—some predictable and others unpredictable. There’s no telling when a natural disaster will upend your supply chain. Take COVID-19, for instance. Many supply chains never planned for a virus that would result in shutdowns and lockdowns and upset supply networks across the world?

Having a global supply chain partner to help you mitigate risks and build a resilient value chain is a must. That’s where Fastbolt comes in. As a provider of global supply chain management solutions for high-quality electro-mechanical products, Fastbolt is an excellent choice for your supply chain needs. We provide program management, inventory management programs, compliance management, engineering assistance, and to our clients.

Our global presence positions us in a unique situation to help solve your needs. Fastbolt is an established market leader that provides an ERP system to offer excellent support for business processes such as sales and distribution, materials management, warehouse management, and finance. So if you want to build a risk resilient supply chain, drop us a line.