Global supply chains are increasingly complicated and more tricky to manage. Many businesses rely on complex global supply networks that span continents and rely on the rapid shipment of goods and parts.

Take Unilever, for instance. Their massive supply chain includes nearly 100,000 employees, working with over 70,000 suppliers and more than 1.5 million farmers. In all, Unilever runs a logistics network that transports over a distance of more than 1.5 billion km each year.

Whether your global supply chain is like Unilever’s or much smaller, you’ll need to get to grips with your global supply chain management. This guide will cover the risks, benefits, and partners you need for a successful supply chain. Also, we’ll provide you with insights on redefining strategic alliances. Ready? Let’s dive in.

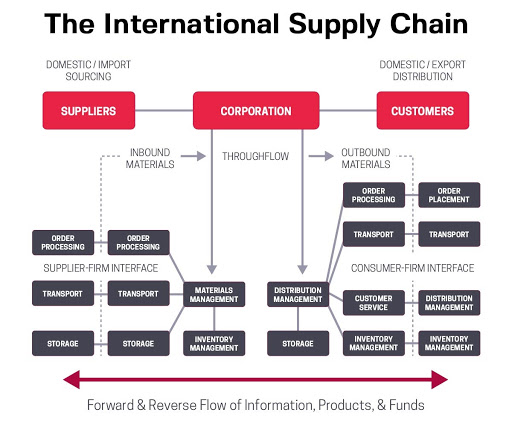

To understand global supply management, you first need to understand the concept of supply chains. A supply chain refers to all the processes involved in sourcing, manufacturing, and bringing a product to the market. It covers sourcing materials, production, transportation, and distribution to the customer’s hands.

A global supply chain is the distribution of goods and services within a trans-national companies global network. Global supply chain management is how you manage and optimize efficiencies at every stage of the supply chain.

Basic supply chain management should cover the following areas:

These are the five core tenets of global supply chains.

Some companies and academics add a category known as “enabling” to their definition of global supply chains. Enabling includes all support services that aid in the optimization of supply chains. That can cover finance, HR, IT, facilities, portfolio management, product design, sales, and quality assurance.

Risks are part and parcel of every supply chain. Whether you’re transporting products through the air, land, or by freight, expect periodic disruptions. While some disruptions are a headache for people involved in global supply chain management, others can result in huge expenses.

According to a research paper by McKinsey and Co., “global disruptions have meant that in every year over the past several years, at least one company in twenty has suffered a supply-chain disruption costing at least $100 million.”

Anticipating and preparing for the potential risks in your supply chain can save you from disaster. Here are the risks associated with global supply chains and how your company can be risk-resilient:

Political stability is hugely important for any business. When you invest in a country, you want to know that those investments are secure. According to the Supply Chain Management Review, political stability is one of the top ten concerns for companies with a global presence.

This desire for political stability is understandable. Major world events like Brexit and the US/China trade wars can, as the example from McKinsey Co. shared earlier, cost companies hundreds of millions of dollars. Prolonged instability can even shape global supply chains.

For example, Tesla decided to base its European Gigafactory in Germany rather than the UK because of Brexit. It’s just one example of how political instability can impact trade and investment decisions.

Before you take your business to a country, study its history, geopolitical landscape, and culture. Consider the implications of political instabilities. A new government, regional tensions, or something else has the potential to bring your supply chain to a standstill.

Alongside political instability, you also have to consider economic stability. From volatile currencies, high inflation rates, unfriendly tax laws, there is a wide range of financial challenges that can cripple your global supply chain. Be careful about the kind of arrangements you enter; otherwise, it might come back to haunt you.

Environmental risks can bring a global supply chain to a screeching halt. In many instances, it may be difficult to avoid an environmental disaster. You can try to mitigate that risk, though. For example, if you are securing supplies from a factory in an earthquake zone, it’s worth considering alternative sources of supplies in the event of a massive earthquake.

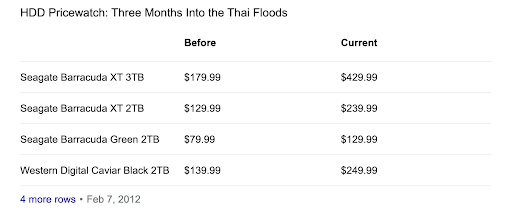

In this instance, you can’t eliminate the risk, but you can reduce the expense associated with these risks. Take the example of the 2012 floods in Thailand.

You might not be aware that Thailand is one of the global production hubs for hard drives. Immediately after the floods that hit the region around greater Bangkok, the price of hard drives skyrocketed.

The scarcity caused by the flooding of factories impacted the global price of hard drives. It would have also impacted any company reliant on hard drives sourced from this region in their global supply chain. Hopefully, this example illustrates the importance of creating backup plans when considering your global supply chain management.

Increased digitization and connectivity have made global supply chains vulnerable to hackers and cyber-attacks. These cyberattacks have a detrimental effect on the running of the business. Case-in-point ASCO Industries: ransomware attacks forced the Belgian Aerospace supplier to close down four of its factories across North America and Europe.

The attack led to a shutdown of the company for more than a month and the furlough of more than 1,000 workers. Global supply chains are even more susceptible to cyber threats, including counterfeits, unauthorized manufacture, theft, and malicious software and hardware insertion.

Who would have thought that a pandemic would ravage the world in 2020 and change the way we live and work? Well, such catastrophes do happen, and they upend the global supply chains.

The coronavirus outbreak led to lockdowns across the world, particularly between March and September 2020. As a result, trade routes were closed, and shipments were delayed or ceased for a significant period. Even in 2021, we have still not recovered from the shockwaves the virus sent around the world’s supply chain.

While there are dangers associated with managing a global supply chain, there are also major benefits. Effective supply chain management, at its core, is about maximizing company profits by optimizing the way you produce products and bring them to market.

Effective supply chain management helps to reduce overhead and operational costs. For example, the ability to correctly predict demand ensures that you don’t store slow-moving inventory, and you can reduce warehouse fulfillment costs.

When you run your global supply chain effectively, you’ll reduce waste and cut out inefficiencies from your system. Reducing inefficiencies can help speed up the route to market. Or, it might involve cutting down the cost of sourcing, production, or shipment. You can also reduce risks associated with your supply chain.

Keep in mind, effective global supply chain management might result in an increase in costs, but an improved product for your customers. Alternatively, there might be a slight increase in cost, but more reliable shipment.

Fundamentally, the benefits of an effective global supply chain market revolve around ensuring your customers get the best product at a competitive price while providing your company with a healthy profit margin. How you achieve those goals will depend on your unique supply chain and your company’s objectives.

International commerce involves a number of important actors. There are a variety of intermediaries you might need to rely on for your global supply chain to operate effectively. Let’s look at some of the crucial partners involved in global supply chains.

Commonly known as foreign freight forwarders or simply forwarders, freight forwarders are companies that organize shipments from the manufacturer to the market, customer, or final distribution point. Most freight forwarders will offer various transport channels, including sea/ocean freight, rail freight, road transport, and air freight shipment.

Freight forwarders perform a number of important roles, including:

In the United States, freight forwarders are regulated by the Federal Maritime Commission. However, it is the U.S. National Customs Brokers and Forwarders Association that certifies forwarders.

Non-Vessel Operating Common Carriers (NVOCCs) do not own or run vessels. However, they buy space on vessels and sell to their customers at competitive rates. An NVOCC will issue its own Bill of Lading. The Bill of Lading is a contract issued by the NVOCC and serves as a contract of carriage.

NVOCCs are an excellent and cost-effective alternative to carriers. They are often described as shippers to carriers and carriers to shippers.

Consolidators, otherwise known as group page operators, help businesses to transport Less than Container Load (LCL) shipments. They combine many small shipments from separate customers. Although consolidators are distinct from NVOCCs, they usually work hand-in-hand.

For small and medium-sized businesses, it can be difficult entering foreign markets. They do not have the same budget and resources that a transnational company or a multinational can command.

Getting your product to a country is only one step in the global supply chain. Passing through customs and clearing them is the next, and depending on the country, can be the more tricky stage.

A customs house broker is an intermediary between an importer or manufacturer and the customs department of a government. They ensure that your papers are in order so you won’t have any run-in with the law. Also, they make payments on behalf of their clients under a power of attorney. Custom house brokers often work with other players in the value chain like forwarders to ensure your shipment is on track.

Export Management Companies (EMCs) provide consultancy services to exporters. A good EMC will have special knowledge and expertise as well as connections to help businesses navigate national bureaucratic procedures. EMCs are typically abreast with local customs and government regulations.

Export Trading Companies (ETCs), on the other hand, provide actual transport services. They perform a wide range of roles, including:

Both an EMC and an ETC can be of invaluable service to a company managing a global supply chain. They can be especially useful for smaller companies, or firms looking to establish operations in a new country.

Shippers associations exist to help businesses ship products cheaply and efficiently by motor carriers, railroads, air carriers, or ocean carriers. Usually formed by a band of small exporters, shipping associations are often non-profits that collectively ship their member’s products at a discount.

A shipping association can pool large volumes of shipments together. This move usually helps them to secure significant shipping discounts for members. The best way to find a suitable shipping association is to contact the relevant trade association for your industry. Alternatively,

Shipbrokers help exporters find the right ships to carry their cargo. Although shipbrokers are independent contractors, they usually have information on the schedule of ships in a port. So, when your cargo is ready, they’ll connect you with an available ship that has the capacity for your cargo.

Ship agents, unlike shipbrokers, work for carriers. A ship agent arranges for a ship’s arrival, berthing, and clearance. Ship agents also coordinate unloading, loading, as well as fee payment.

Export packing companies help you prepare your cargo for long journeys. Packaging of your goods is important for a number of reasons. First, a product that’s properly packaged will move through customs faster. For example, in certain countries, the import duty you pay is dependent on not just the weight of your cargo but the packaging as well.

Specialized packaging will also ensure that your product is able to endure rough handling and harsh climates, and arrives at its destination undamaged. That can reduce the cost of returns. Finally, carefully packaged goods, that are properly itemized, can be unloaded quickly. That can reduce the work for the people receiving the goods.

This guide provided you with an overview of global supply chain management. We looked at some of the benefits and risks associated with managing a global supply chain. We also looked at some of the primary actors involved in global supply chains.

To run an effective supply chain, you’ll need to source suitable materials and build relationships with partners. Those bridges you will build with your allies will pay dividends in the long term. Of course, identifying suitable partners and suppliers will take time. There are risks that can cost your business if things go wrong.

Fastbolt has a global presence, with a presence in China, Taiwan, Europe, Latin America and the US. We are a key supplier in the global supply chain for leading global companies. We can help with diversified sourcing and risk mitigation, compliance management, and more. Drop us a line to discover how we can help support your business needs.